- Services

- Mechanical Engineering Services in Australia

- Structural Engineering Service in Australia

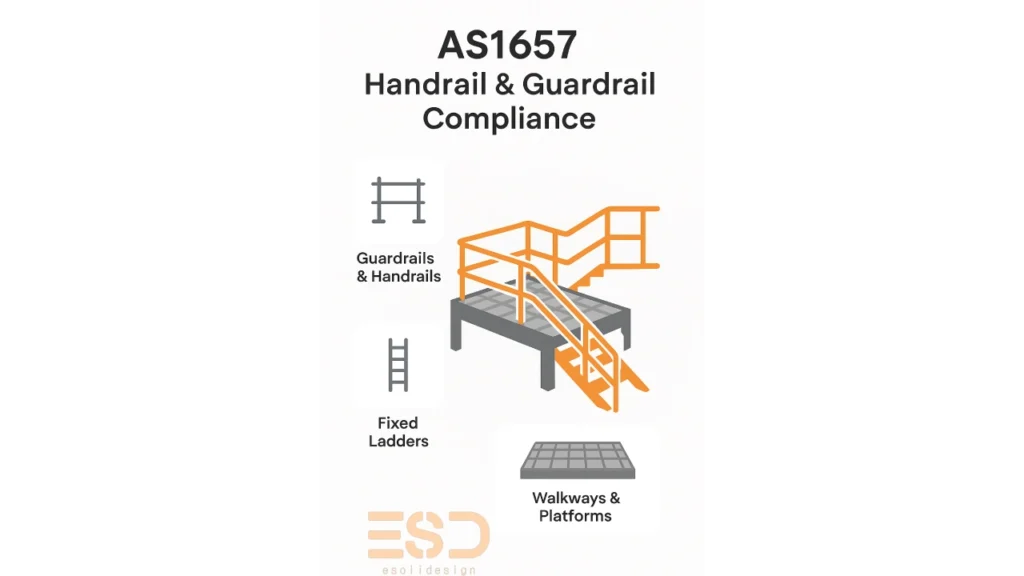

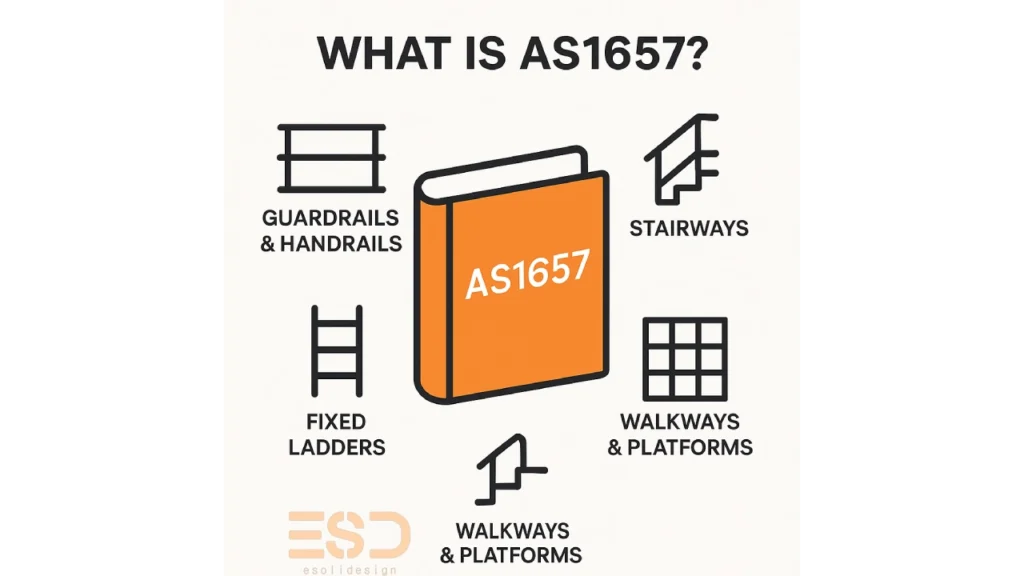

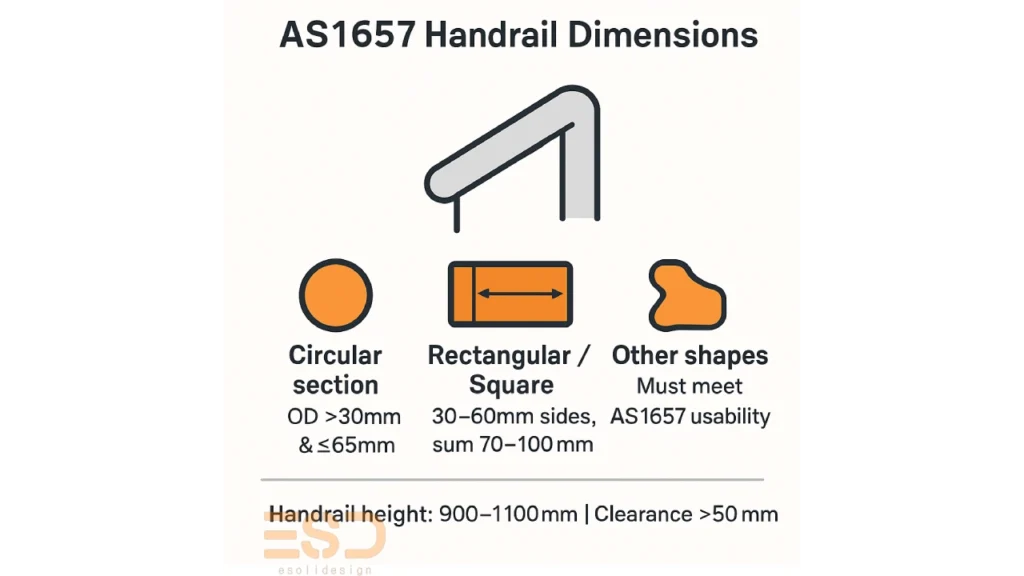

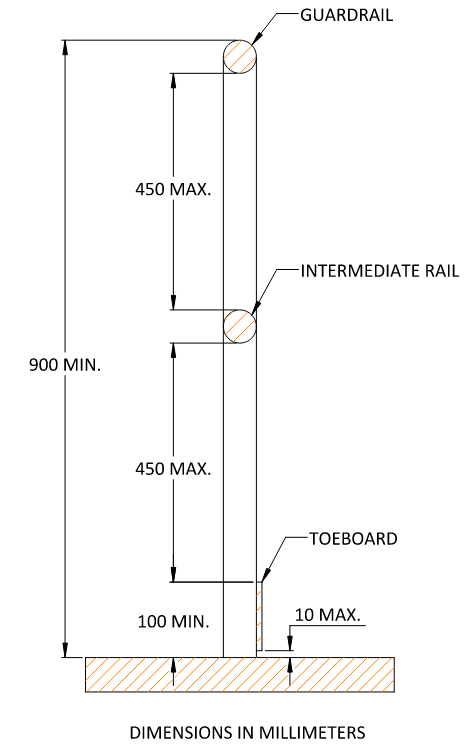

- Handrail & Balustrade Design and Certification — AS1657 | AS1170 | AS1428

- Certification Services in Victoria & Queensland

- New Product Development in Australia

- Simple, Transparent Pricing

- 3D CAD Modelling & Detailed Drafting Services in Australia

- Portfolio

- Testimonial

- ABOUT US

- Contact Us

- Blog

Have Any Questions?

0488 383 308