In this whitepaper we are going to review the linear buckling analysis. This is one of the most useful analysis to evaluate the part/ assembly behavior under axial load. By this analysis we could find the minimum critical amount of load that causes model instability.

The common assumption is that small displacements eliminate the necessity for additional nonlinear analysis, although this isn’t always the case.

In this session, we will review this analysis by finding the minimum amount load (load factor) for the silo base frame instability under axial (compression) load.

Problem Description

In this whitepaper, we are analyzing a grain silo base frame and we are going to find the load factor for the base frame instability. The diameter is about 8.0m and height of frame is about 3.0m.

Material for this analysis is carbon steel grade 300.

Creating the Study

Click on the new study icon, name the study as you wish, here it is called Buckling Analysis and select Buckling analysis, figure (1).

Apply Material

Next, Right click on Parts icon and select Apply Material to All…, figure (2); then, select “Plain Carbon Steel”.

To save time and energy of the machine without scarifying the analysis accuracy convert all beam sections into beam element. To do this, you need to right click on each individual part and select Treat as Beam…, figure (3).

After converting all beam sections into beam elements, the model will be like figure (4), after that the Joint group will be added to the analysis tree, figure (5).

Pink dots indicate that the beam elements are connected at this point, while green dots signify that the joint end is unrestricted and can be linked to other shell/solid elements.

Also, convert the thin materials into sheet metal. For this, right click on the sheet metal part and select Define Shell By Selected Faces…, figure (6).

An important note about shell define is that, you should always remember which side of shell you selected for the shell definition. All contacts, fixings and loads shall be applied on the selected face for shell definition.

Set the connections

Add bonded contact between all parts, for the beam elements select them at the first set and the mating surface/ line at the second set, figure (7).

If you need to modify a join between couple of beam elements, to add or remove a section, follow this steps:

- Right click on the joint group in the assembly tree, select Edit…,

- Then, right click on the joint the you want to modify; then by clicking on an element add or remove it from the joint member groups, figure (8).

Apply Fixtures

Add fixed fixture to the all base plates.

Define the loads

In this analysis type, we focus on determining the load factor rather than examining the stress distribution within the model. Once we find the load factor, we will multiply it by the applied load at this stage, which is 1000N, to calculate the load for the base frame instability, figure (9).

Mesh the Model

For this analysis, slide the mesh density slide to the right (fine), select high quality and mesh type as Curvature-based mesh type, figure (10).

Run the Analysis

Then, run the analysis.

Evaluate the Results

As figure (11) represents, the load factor is about -152; so that the instability load for this model, the first mode of buckling is 152kN.

Regarding to the negative sign of the load factor, based on the figure (12), buckling is not expected.

What is Next:

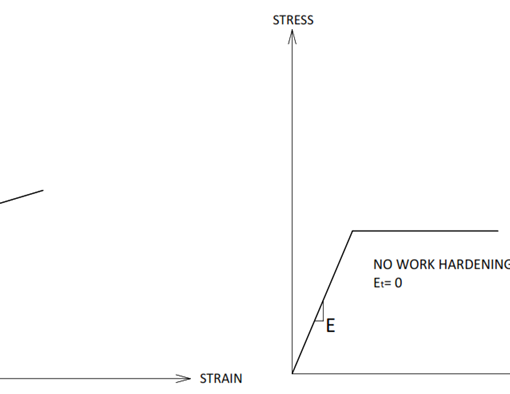

On the next whitepaper, we will explore about Non-Linear Analysis.