Reading Time: about 5 minutes.

In this paper we try to answer the common question of “If my model mesh quality is good enough or not?”. Before responding to this question we need to have a look at what we need to do before meshing and define the terms related to mesh quality like aspect and Jacobian ratios.

Pre-Mesh Step

We need to know the difference between CAD model and FEA model. While the CAD model has all details for manufacturing and finishing, the FEA model only needs to have the necessary elements. Obviously, the recognition of necessary elements requires meticulous engineering considerations.

This step is called defeaturing and the main purpose of this step is to convert a CAD model into a meshable FEA geometry.

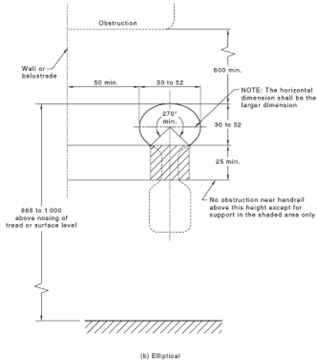

As a general rule, it is recommended to clean-up all small faces and short edges, figure (1).

Mesh Quality

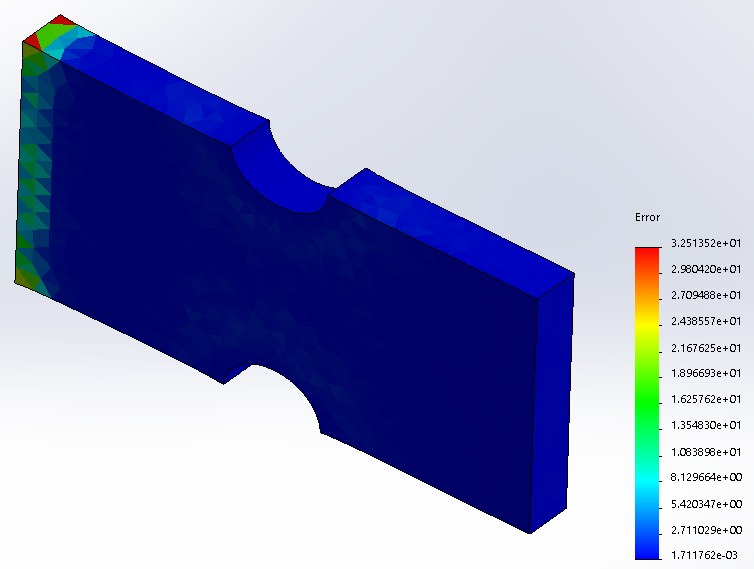

Most of the models that are analyzed have some degree of complexity; so, there is always a degree of distortion to the mapped elements. This element distrosion could be controlled by default element size and local mesh control.

We always could get a report for mesh quality of CAD model. In addition to mesh quality, we could get plot for aspect ratio and Jacobian. These two are discussed in this section.

Aspect Ratio

The ideal solid tetrahedral/ shell triangular elements have equal length edges. In reality it is not possible to have all edges the same. When the element edge’s lengths become more and more different, the results accuracy drops.

The aspect ratio of each element is compared to the ideal element with aspect ratio of 1, all edges have the same length, figure (2).

Aspect ratio of each element is equal to the ratio of the longest edge to the shortest edge, figure (3).

Jacobian Check

When second order elements are mapping a sharp change in geometry; sometimes, placing a mid node on exact geometry would distort the element shape and make edges overlap each other (distorted element).

The jacobian ratio of a correct element (parabolic element with all mid nodes exactly located at the middle of straight edge) is 1.0. While, the jacobian ratio of the distorted element would be negative. An element with negative Jacobian number fails the analysis. A correct and a distorted element are presented in figure (4).

For SolidWorks Simulation Jacobian ratio of 40 or less is acceptable. By reducing global element size or using mesh controls, element shape distortion could be controlled.

Mesh Control

So far, we mentioned mesh control. Now, it is time to explain it more. Mesh control could be applied to vertices, edges, faces and assembly parts, figure (4).

To define mesh control, you need to specify these features:

- Element size on the target (how small the elements at the target region should be),

- The growth ratio of element (how small element at the target region grow to reach model general mesh size), figure (5).

Meshing Tips

- As a general rule, to save available computer resources, it is recommended to mesh the part/ assembly with the recommended element size by software, run the analysis; then, use mesh control tool to modify the element size of high stress areas or areas that you have concern about.

- It is possible to have failed mesh in the analysis. There are couple of techniques to resolve it:

First, you could use “mesh failure diagnostic” tool to find the failure section; then modify the model or apply enough small mesh size for that section.

Second, if you couldn’t get enough information from “mesh failure diagnostic”, roll back the model to the feature that you can get the part meshed and modify the part from there.

- Before meshing an assembly, use “Interference Detection” to check if the parts have any interference or not. Except for “shrink fit” analysis no interference is allowed for other contact types.

It is a good time to discuss solvers in SolidWorks Simulation and how to select them.

Solver Seletion

There are four types of solvers in SolidWorks Simulation, three direct and one iterative solver:

- Direct Sparse Solver.

- Large Problem Direct Sparse,

- Intel Direct Sparse,

- FFEPlus (iterative).

Direct VS Iterative Solver

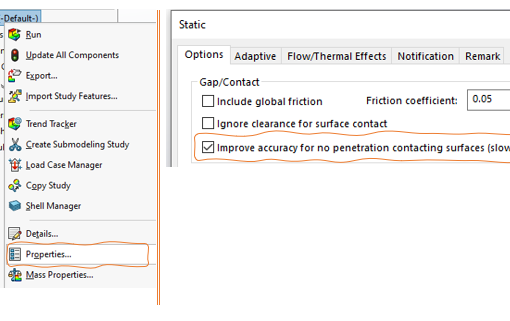

The direct solvers try to solve the FEA equations by exact numerical methods; while, iterative solver approximates the solution and each time evaluates the error term until the error is in acceptable range. When there is a considerable difference between material properties (e.g. Elastic Modulus) direct solvers are more accurate.

Problem Size

As a general rule, for each 200,000 degree of freedom, 1GB of RAM is required. When there is enough RAM and CPU on the machine, Direct Sparse and FFEPlus are better selections.

Due to using advanced matrix recording, the FFEPlus solver is more efficient for large problems.

Both Large Problem Direct Sparse and Intel Direct Sparse, utilise enhanced memory allocation algorithms to be more efficient for solving models that require more resources than available RAM and CPU on a machine.

Type of Analysis

Static:

Direct solvers are better for static analysis and based on the model size, select between Direct Sparse, Large Problem Direct Sparse, Intel Direct Sparse.

Frequency and Buckling:

For analysing any rigid body modes, FFEPlus is a better solver. Having said that, if you are going to check the loading effect on the natural frequencies; or, using incompatible mesh; or, using soft springs to stabilise the model, based on the model size, Direct Sparse pr Intel Direct Sparse are better solvers.

Thermal and Nonlinear:

For both of these analyses if you are working with large models (500 dof for thermal analysis and 50K dof for nonlinear analysis) FFEPlus is more effective.

* The main reference for Solver Selection is SolidWorks online Help.

What is Next:

In the next paper, we start to solve the first FEA problem and see how to use software features.