ESD’s design team began by reviewing the original hand sketches, field photographs, and operational feedback provided by Regent Solutions.

Through close collaboration, both teams exchanged design insights and field observations to ensure the new Pull Tee would meet the client’s performance expectations and installation standards.

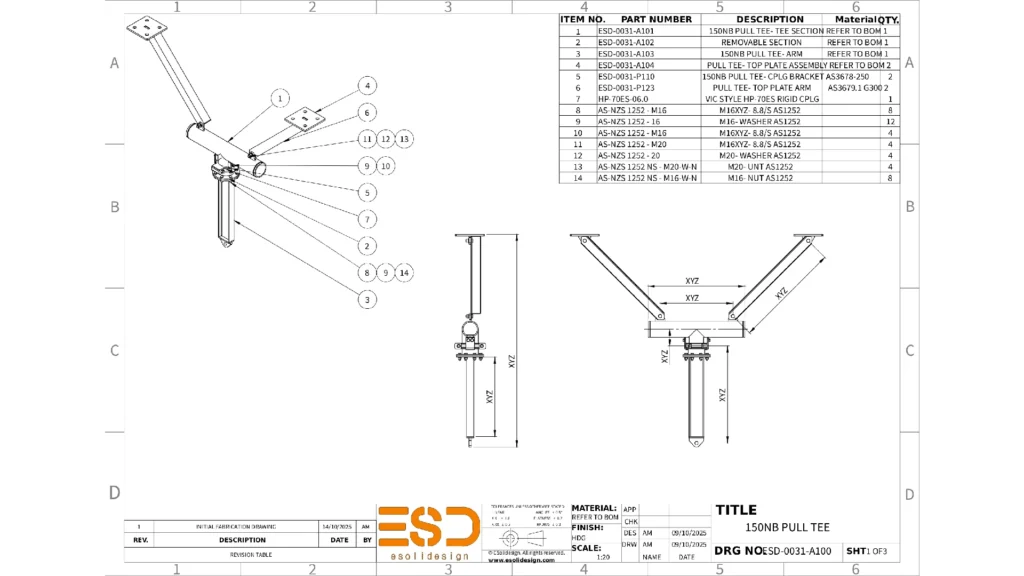

A new 3D CAD model was developed, integrating a flanged connection at the tee leg to make it replaceable in the field.

The design also incorporated a reinforced coupling and guide saddle arrangement that controlled where deformation occurred under pulling load — ensuring the leg became the predictable failure point while protecting the main tee body.

Throughout the design process, Regent Solutions provided valuable feedback drawn from practical field experience.

ESD implemented these inputs into the final geometry, confirming that the new configuration aligned with on-site installation practices, preferred weld orientations, and maintenance routines.

Structural checks and geometric validation verified that the leg shears safely under defined loads while maintaining full operational integrity of the main assembly.

The resulting design balances structural reliability, field serviceability, and manufacturing consistency, all refined through collaboration with the client’s engineering and maintenance teams.